Standards: ASTM B-21, ASTM B-124, ASTM B-171, SAE J461, SAE J463, SAE 73, AMS 4611, AMS 4612, DIN 3.053

Naval Brass C46400 is nominally composed of 60% copper, 39.2% zinc, and 0.8% tin. As is typical of brass alloys with the duplex alpha beta structure, C46400 has good strength and rigidity. By substituting tin for an equal quantity of zinc, a high corrosion resistance to seawater is achieved. The addition of tin also gives the alloy an inherent resistance to dezincification, thereby further inhibiting the impingement by seawater at higher than normal temperatures. The alloy is also noted for its resistance to wear, fatigue, galling, and stress corrosion cracking.

Typical Uses for C46400 Naval Brass "Lead-Free":

BUILDERS HARDWARE: Lock Pins

ELECTRICAL: Precision Shipboard Equipment

FASTENERS: Rivets, Bolts, Nuts

INDUSTRIAL: Welding Rod, Condenser Plates, Structural Uses, Valve Stems, Balls, Heat Exchanger Tube, Turn Buckle Barrels, Bearings, Dies, Pressure Vessels, Bearings, Bushings, Hub Cones

Propeller Shafts, Marine Hardware, Decorative Fittings, Shafting, Propeller Shafts, Turnbuckles

ORDINANCE: Missile Components

OTHER: Baffle Plates and Flanges

PLUMBING: Fittings

Shapes & Sizes Available From NBM

SOLID BAR . . . . . . . . . . . . 3/16" - 12" diameter

HEX & SQUARE BARS . . . . up to 3"

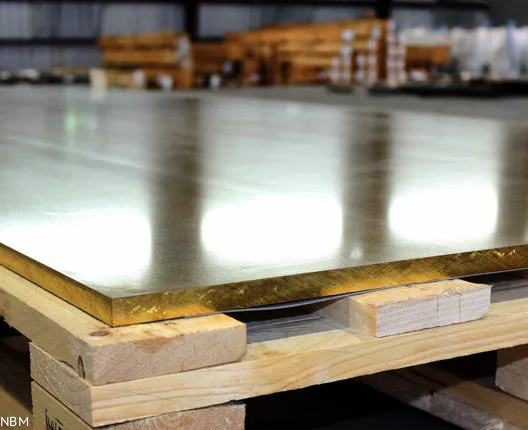

PLATES (HOT ROLLED) . . . .cut to size, up to 6" thick

SHEETS (COLD ROLLED) . . up to 1/4" thick

DISCS . . . . . . . . . . . . . . . . .cut to size, up to 6" thick

C46400 Naval Brass Specifications

| End Product | Specification |

| Bar | AMS 4611, 4612, ASTM B21, FEDERAL QQ-B-639, SAE J463, J461 |

| Bar, Forging | ASTM B124 |

| Bolts | ASTM F468 |

| Forgings, Die | ASTM B283 |

| Nuts | ASTM F467 |

| Plate | FEDERAL QQ-B-639 |

| Plate, Clad | ASTM B432 |

| Plate, Condenser Tube | ASME SB171, ASTM B171 |

| Rod | AMS 4611, 4612, ASTM B21, SAE J463, J461 |

| Rod, Forging | ASTM B124 |

| Screws | ASTM F468 |

| Shapes | ASTM B21 |

| Shapes, Forging | ASTM B124 |

| Sheet | FEDERAL QQ-B-639 |

| Strip | FEDERAL QQ-B-639, SAE J463, J461 |

| Studs | ASTM F468 |

| Wire, Metallizing | MILITARY MIL-W-6712 |

| Cu | Fe | Pb | Sn | Zn | |

| Min/Max | 59.0 - 62.0 | 0.1 | 0.2 | 0.5 - 1.0 | Rem |

| Nominals | 60.0000 | - | - | 0.7000 | 39.2000 |

| Product Type | Temper Type |

| Bar | AMS 4611, 4612, ASTM B21, FEDERAL QQ-B-639, SAE J463, J461 |

| Bar, Forging | ASTM B124 |

| Bolts | ASTM F468 |

| Forgings, Die | ASTM B283 |

| Nuts | ASTM F467 |

| Plate | FEDERAL QQ-B-639 |

| Plate, Clad | ASTM B432 |

| Plate, Condenser Tube | ASME SB171, ASTM B171 |

| Rod | AMS 4611, 4612, ASTM B21, SAE J463, J461 |

| Rod, Forging | ASTM B124 |

| Screws | ASTM F468 |

| Shapes | ASTM B21 |

| Shapes, Forging | ASTM B124 |

| Sheet | FEDERAL QQ-B-639 |

| Strip | FEDERAL QQ-B-639, SAE J463, J461 |

| Studs | ASTM F468 |

| Wire, Metallizing | MILITARY MIL-W-6712 |

| Temper | Sect. Size | Cold Work | Type Min | Temp | Tensile Strength | YS 0.05% UL | YS 0.02% Offset | YS 0.005% Offset | Elong. | RH B | RH C | RH F | RH 30T | VH 500 | BH 500 | BH 3000 | Shear Strgth | Fatigue Strgth | Izod Impact Strgth |

| - | in. | % | - | F | ksi | ksi | ksi | ksi | % | B | C | F | 30T | 500 | 500 | 3000 | ksi | ksi | ft-lb |

| - | mm. | - | - | C | MPa | MPa | MPa | MPa | - | - | - | - | - | - | - | - | MPa | MPa | J |

| FLAT PRODUCTS | |||||||||||||||||||

| O50 | 0.04 | 68 | 62 | 30 | - | - | - | - | - | - | - | - | - | - | 41 | - | |||

| O50 | 1 | 0 | TYP | 20 | 427 | 207 | - | - | 40 | 60 | - | - | 57 | - | - | - | 283 | - | 0 |

| O50 | 0.25 | 68 | 60 | 28 | - | - | - | - | - | - | - | - | - | - | 41 | - | |||

| O50 | 6.35 | 0 | TYP | 20 | 414 | 193 | - | - | 45 | 58 | - | - | 56 | - | - | - | 283 | - | 0 |

| H01 | 0.04 | 68 | 70 | 58 | - | - | - | - | - | - | - | - | - | - | 43 | - | |||

| H01 | 1 | 0 | TYP | 20 | 483 | 400 | - | - | 17 | 75 | - | - | 68 | - | - | - | 296 | - | 0 |

| M20 | 1 | 68 | 55 | 25 | - | - | - | - | - | - | - | - | - | - | 40 | - | |||

| M20 | 25.4 | 0 | TYP | 20 | 379 | 172 | - | - | 50 | 55 | - | - | 55 | - | - | - | 276 | - | 0 |

| O60 | 0.25 | 68 | 58 | 25 | - | - | - | - | - | - | - | - | - | - | 40 | - | |||

| O60 | 6.35 | 0 | TYP | 20 | 400 | 172 | - | - | 49 | 56 | - | - | 55 | - | - | - | 276 | - | 0 |

| ROD | |||||||||||||||||||

| H02 | 0.25 | 68 | 80 | 57 | - | - | - | - | - | - | - | - | - | - | 45 | - | |||

| H02 | 6.35 | 20 | TYP | 20 | 552 | 393 | - | - | 20 | 85 | - | - | - | - | - | - | 310 | - | 0 |

| H01 | 1 | 68 | 69 | 46 | - | - | - | - | - | - | - | - | - | - | 43 | - | |||

| H01 | 25.4 | 8 | TYP | 20 | 476 | 317 | - | - | 27 | 78 | - | - | - | - | - | - | 296 | - | 0 |

| O50 | 2.01 | 68 | 62 | 28 | - | - | - | - | - | - | - | - | - | - | 42 | - | |||

| O50 | 51 | 0 | TYP | 20 | 427 | 193 | - | - | 43 | 60 | - | - | - | - | - | - | 290 | - | 0 |

| H02 | 1 | 68 | 75 | 53 | - | - | - | - | - | - | - | - | - | - | 44 | - | |||

| H02 | 25.4 | 20 | TYP | 20 | 517 | 365 | - | - | 20 | 82 | - | - | - | - | - | - | 303 | - | 0 |

| O50 | 0.25 | 68 | 63 | 30 | - | - | - | - | - | - | - | - | - | - | 42 | - | |||

| O50 | 6.35 | 0 | TYP | 20 | 434 | 207 | - | - | 40 | 60 | - | - | - | - | - | - | 290 | - | 0 |

| O60 | 2.01 | 68 | 56 | 25 | - | - | - | - | - | - | - | - | - | - | 40 | - | |||

| O60 | 51 | 0 | TYP | 20 | 386 | 172 | - | - | 47 | 55 | - | - | - | - | - | - | 276 | - | 0 |

| H01 | 2.01 | 68 | 67 | 40 | - | - | - | - | - | - | - | - | - | - | 43 | - | |||

| H01 | 51 | 8 | TYP | 20 | 462 | 276 | - | - | 35 | 75 | - | - | - | - | - | - | 296 | - | 0 |

| O50 | 1 | 68 | 63 | 30 | - | - | - | - | - | - | - | - | - | - | 42 | - | |||

| O50 | 25.4 | 0 | TYP | 20 | 434 | 207 | - | - | 40 | 60 | - | - | - | - | - | - | 290 | - | 0 |

| O60 | 1 | 68 | 57 | 25 | - | - | - | - | - | - | - | - | - | - | 40 | - | |||

| O60 | 25.4 | 0 | TYP | 20 | 393 | 172 | - | - | 47 | 55 | - | - | - | - | - | - | 276 | - | 0 |

| O60 | 0.25 | 68 | 58 | 27 | - | - | - | - | - | - | - | - | - | - | 40 | - | |||

| O60 | 6.35 | 0 | TYP | 20 | 400 | 186 | - | - | 45 | 56 | - | - | - | - | - | - | 276 | - | 0 |

| H01 | 0.25 | 68 | 70 | 48 | - | - | - | - | - | - | - | - | - | - | 43 | - | |||

| H01 | 6.35 | 10 | TYP | 20 | 483 | 331 | - | - | 25 | 80 | - | - | - | - | - | - | 296 | - | 0 |

| TUBE | |||||||||||||||||||

| H80 | 0 | 68 | 88 | 66 | - | - | - | - | - | - | - | - | - | - | - | - | |||

| H80 | 0 | 35 | TYP | 20 | 607 | 455 | - | - | 18 | 95 | - | - | - | - | - | - | - | - | 0 |

| Product Property | US Customary | Metric |

| Coefficient of Thermal Expansion | 11.8 ÌÎ?̴ÌÁ10-6 per oF (68-572 F) | 21.2 ÌÎ?̴ÌÁ 10 6? per ÌÎ?̴åÁC (20-300 C) |

| Density | 0.304 lb/in3 @ 68 F | 8.41 gm/cm3 @ 20 C |

| Electrical Conductivity | 26 %IACS @ 68 F | 0.152 MegaSiemens/cm @ 20 C |

| Electrical Resistivity | 39.9 ohms-cmil/ft @ 68 F | 6.63 microhm-cm @ 20 C |

| Melting Point Liquid US | 1650 F | 899 C |

| Melting Point Solid US | 1630 F | 888 C |

| Modulas of Elasticity in Tension | 15000 ksi | 103400 MPa |

| Modulas of Rigidity | 5600 ksi | 38610 MPa |

| Specific Gravity | 8.41 | 8.41 |

| Specific Heat Capacity | 0.09 Btu/lb/ÌÎ?̴åÁF @ 68 F | 377.1 J/kg ÌÎ?̴ÌÁ ÌÎ?̴åÁK at 293 K |

| Thermal Conductivity | 67.0 Btu ÌÎ?̴ÌÁ ft/(hr ÌÎ?̴ÌÁ ft2 ÌÎ?̴ÌÁÌÎ?̴åÁF) @ 68 F | 116.0 W/m ÌÎ?̴ÌÁ ÌÎ?̴åÁK at 20 C |

| Joining Technique | Suitability |

| Brazing | Excellent |

| Butt Weld | Good |

| Capacity for Being Cold Worked | Fair |

| Capacity for Being Hot Formed | Excellent |

| Coated Metal Arc Welding | Not Recommended |

| Forgeability Rating | 90 |

| Gas Sheilded Arc Welding | Fair |

| Machinability rating | 30 |

| Oxyacetylene Welding | Good |

| Seam Weld | Fair |

| Soldering | Excellent |

| Spot Weld | Good |